Big Dutchman Southern Africa is proud to share another successful turnkey broiler project, fully designed, built, and equipped by our in-house team – from the foundations to the finishing touches.

On the construction side, our skilled team managed every aspect of the build, including concrete works, steel structure, roofing, and painting, ensuring durable, high-quality facilities built to Big Dutchman standards.

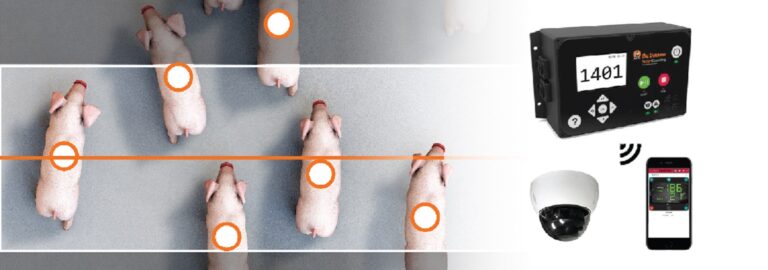

The equipment installation included everything from the silos and batch weighers through to the automated feeding, drinking, and ventilation systems, creating a complete, integrated production environment. Each house is fitted with a Breezy climate controller and automated curtains that operate via a weather station, ensuring precise environmental control and energy efficiency.

For optimal bird performance, the houses feature Viva 330 feeding pans, top orange nipples on the drinker lines, and a split feeding and drinking line system for balanced access. Ventilation is powered by ten VC 130 fans per house, complemented by a high-pressure cooling system for consistent climate regulation.

This project demonstrates how Big Dutchman Southern Africa continues to set the standard in modern poultry production, offering total solutions that work seamlessly together to support sustainable growth across the region.