Different mills and screens can be used based on individual requirements, such as feed having more structure or fine milling. The correct supply of the material to be milled by the dosing auger is monitored using a special milling control system, meaning an automatic adaptation of the delivery rate to the conveyed material type.

The throughput requirements decide the mill type (single, double, or parallel mill) to be installed. The transportation of the milled meal can be done using several of the conveyor elements like trough augers, buckets or chain elevators.

Technical

- The hammer mills can work at a driving power ranging from 11 to 45 kW

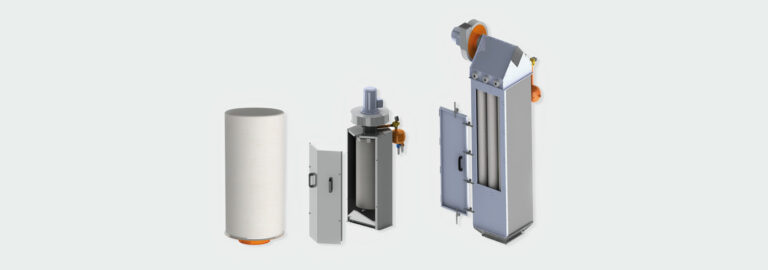

- A hammer mill comprises of a housing, a grinding bridge, a rotor having rotating hammers, engine, and screens

- The location of the inlet is in the opposite direction of the engine