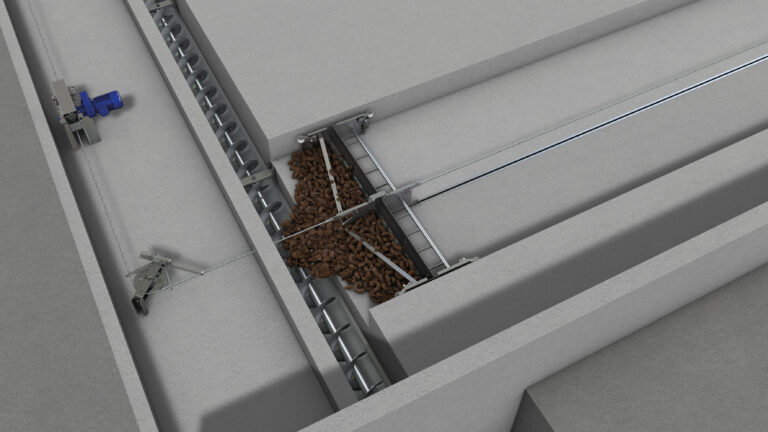

CompoLiner is an innovative composting system that offers easy handling, as well as a guided, fully automatic process control. The installation is quick and easy, and the system is easily adaptable to the amount of material to be composted.

During the composting process, organic material such as dry poultry excrement, broiler manure or separated slurry is broken down by microorganisms in an aerobic environment, resulting in a dry matter content of at least 30 percent.

The end result is compost, which is a valuable organic fertiliser that can be used in horticulture and agriculture as is or turned into pellets as a more hygienic option.

Emission Reduction in Composting

The composting process will naturally produce certain emissions, such as dust, ammonia and odour. As this may not be acceptable in certain locations, the use of an exhaust air cleaner is highly recommended.

For your convenience, a chemical exhaust air cleaner has been developed specifically for CompoLiner. It comes pre-built and ready to connect in a 40-foot container or mounted on a truck with minimal installation requirements.

Technical

- Modular design: the basic version consists of two 40-foot containers that also serve as end sets

- Up to six additional 40-foot containers can be installed between the end sets for a total capacity between 80 and 360 m³ and approx. 50,000 up to 200,000 layers

- Exhaust air cleaner:

- Delivery in a 40-foot container

- Individual placement: connection through a duct of the correct size